In recent years Smink Group has developed advanced systems for in-line, real-time measurement of impurities in gases using Ion Mobility Spectrometry (IMS). The system enables real-time measurement of multiple contaminants simultaneously at various levels on a parts per billion and trillion level. These systems are specifically designed to suit a variety of environments, offering precise monitoring and exceptional sensitivity.

Each system is customized and configured to match the unique demands of its environment, providing reliable and efficient solutions for impurity monitoring.

Cleanroom Environments

- Detection Sensitivity: Low ppb level.

- Application: Real-time monitoring impurities in cleanrooms across different purity levels, ensuring strict contamination control. Data storage of IMS spectra for RGA of contamination.

Inert & Hydrogen Environments

- Detection Sensitivity: Low ppb or ppt level depending on environment.

- Application: Real-time impurity analysis in inert and hydrogen-based systems, maintaining process integrity in challenging conditions.

High-Purity Systems

- Detection Sensitivity: ppt level.

- Application: Measuring trace impurities in ultra-high-purity systems with minimal contamination levels.

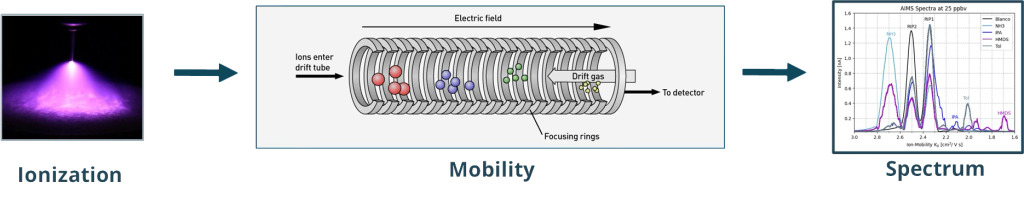

Working principle

Gas is ionized and measured in the basic set up as shown below.

High-accuracy real-time monitoring: The systems enable precise, in-line real-time measurement of impurities.

Measurement of multiple contaminations: The system enables real-time measurement of multiple contaminants simultaneously.

Cost-effective solution: Competitive pricing makes these systems an economical choice compared to other analytical methods with similar performance.

Context-dependent precision: Accuracy is influenced by the type of contamination and the specific background conditions.

Proactive alerts and data collection: Equipped with alarm functionality, the systems notify users when pre-set limits are exceeded and continuously gather data for detailed analysis.

Contamination measurement at atmospheric pressure: no need for vacuum system.

High-Purity testing with IMS Technology

Smink Group offers a High-Purity Test Setup for customer-specific testing. We welcome you to share your challenges with us for collaborative testing to explore how IMS technology can benefit your applications.

We welcome the opportunity for an open, face-to-face discussion with your technical team to explore potential applications, including:

- In-Machine Measurements: Monitoring in-line, real-time purity levels for improved process control.

- In-Room Measurements: Preventing yield loss by detecting and addressing increased contamination levels.

- In-Cabinet Measurements: Reducing process risks and enhancing efficiency by monitoring load locks and wafer transfer systems, minimizing purge and stabilization times, and optimizing cleaning cycles.